In high-output industrial settings, every percentage of uptime matters. Machines are maintained with precision, production lines are optimised, and operations are digitally monitored. Yet one of the most impactful elements of workplace performance often goes unaddressed — air quality.

We now know poor indoor air conditions contribute directly to increased absenteeism, impaired cognitive function, and higher long-term health risks. And while many organisations still view air purification as a safety checkbox, leading manufacturers are integrating it as a strategic performance tool.

Air Quality Affects Output — And Science Can Prove It

The health implications of fine particulate matter (PM2.5 and PM10) are well documented. But what’s often missed is their operational impact on human performance.

A joint study by Harvard University and Syracuse University found that reducing indoor air pollutants improved cognitive function by up to 61% across several domains, including crisis response and information usage.

🔗 Source

In another European study conducted across manufacturing sectors, workers exposed to consistently high PM2.5 levels experienced 12–20% higher absenteeism and fatigue-related underperformance.

🔗 Source

The point is clear: polluted air doesn’t just harm lungs — it quietly degrades your daily output.

The PMR Tube: A Smart Shift from Filtration to Active Air Management

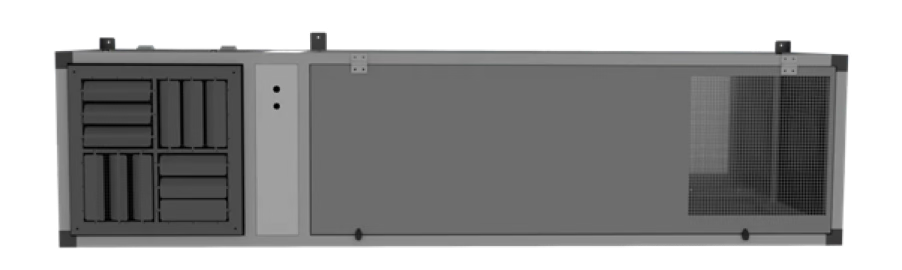

Unlike conventional air purifiers that rely on air circulation and heavy filtration, the PMR Tube by StaticAir operates through positive ionisation technology — a more advanced, active method of removing airborne particulates at the source.

How it works:

- The PMR Tube emits positively charged ions into the air.

- These ions attract and bond with fine dust particles like PM10 and PM2.5.

- As they bond, the particles become heavier and drop out of the air — significantly reducing breathable pollutants in the environment.

Core features of the PMR Tube:

- ✅ No filters to replace — no ongoing maintenance costs

- ✅ Silent operation — ideal for production environments

- ✅ IoT-enabled — allows real-time air quality monitoring and control

- ✅ Extremely low energy consumption — continuous 24/7 operation

- ✅ Modular setup — flexible installation in workshops, recycling facilities, and production lines

The PMR Tube is already actively used in European industrial facilities — particularly in:

- Woodworking operations

- Recycling and plastic processing

- Fabrication and welding zones

Field results have shown up to 55% reduction in fine particulate levels in active industrial settings — making it one of the most effective systems for managing industrial air pollution without disrupting operations.

Not a Cost Centre — A Performance Multiplier

Air purification shouldn’t be treated as a peripheral upgrade. It impacts core metrics:

- 📉 Fewer sick days and absenteeism

- ⚙️ Lower error rates and fatigue-related slowdowns

- ✅ Improved ESG performance, aligned with Scope 3 standards

- 🛡️ Reduced risk and better compliance with tightening indoor air regulations

A clean-air strategy using the PMR Tube positions organisations for long-term operational resilience and health-focused performance culture.

Learn More

To understand how the PMR Tube can integrate into your factory or plant, and see case studies from European deployments:

👉 Explore the PMR Tube on StaticAir’s Official Website

Because in today’s industrial landscape, clean air isn't just a health priority — it's a business advantage.